With growing eCommerce channels and increased online shopping behavior, omnichannel retailers are grappling with the increased complexity brought on, in part, by current events, but more so the anticipated need to combine online and in-store merchandising, especially for the “new normal”. Siloed decisions around allocation, promotions, in-season pricing, inventory transfers and fulfillment will fail to deliver the expected margin performance unless they address the interconnectedness of online and stores.

Retailers’ in-season inventory management, now more than ever, needs a more unified approach, taking into consideration entwined dynamics on five dimensions:

- Where will the customer buy – online or in-store – over the season and at what price?

- How will they take receipt of their purchase – buy in-store, pickup in-store; buy online, curbside or in-store pick up; buy in-store, deliver to home; or simply buy online, deliver to home?

- Where does the customer live in proximity to the store or DC?

- If and where the customer is likely to return the purchase?

- How many items are included in the order?

Efforts to manage for inventory understock, overstock and sales growth with these additional multi-channel combinations has become a mind-boggling challenge, made more important given the swing toward more online purchasing in recent months.

How leveraging a common view of demand and fulfillment can help – an example

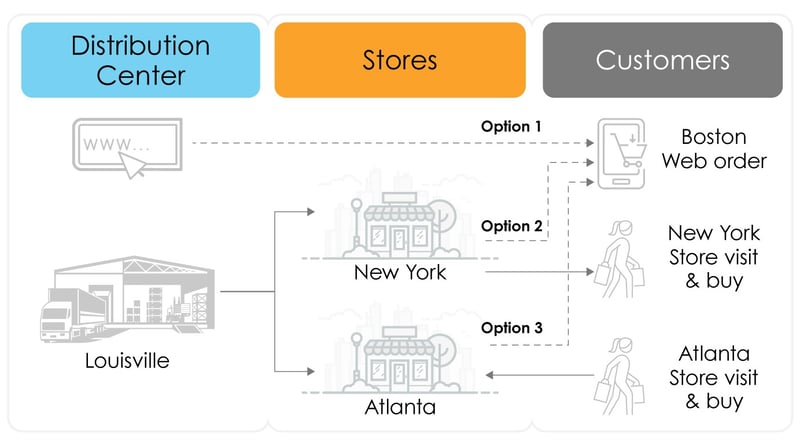

Take the simple case of an online customer with a single order from, say, Boston, where there is no store. Should this order be fulfilled from the DC in Louisville, the New York store or the Atlanta store?

Multiple factors need to be considered:

- Louisville DC is designed for multi-item orders to reduce high shipping costs, therefore shipping from the DC would be sub-optimal since the order is only a single item.

- New York store is the closest, and shipping would be the same cost as from the DC, but the inventory of that item is forecasted to turnover fast, therefore expected to maintain the predicted price of $27.

- Atlanta, on the other hand, is forecasting a slower turnover, therefore has a predicted markdown dropping the future price to only $19, and the incremental shipping cost over New York is only $2.

It is no longer a straight-forward choice to ship from the DC, nor the closest store. Rather, the right choice is to fulfill the order from a less valuable inventory pool where the additional shipping cost is far less than the potential revenue gain.

Complexity beyond the ability for Excel to handle

This complex combination of factors highlights the level of uncertainty, and risk, that retailers need to manage. Demand will shift between brick-and-mortar and on-line, and top doors in places like resort destinations may see a steeper decline. Staying on top of current demand and unknown potential of returns, and its impact on your overall inventory picture, is impossible to conquer with spreadsheets alone. Traditional models of categorizing stores into alpha buckets based on history will not capture the ever-shifting dynamics of the emerging retail market.

In addition, without an automated way to incorporate demand to optimize allocation, pricing and fulfillment recommendations into the inventory management process, planners are limited to Excel-like tools. Spreadsheets are constrained to prices based on rules-based forecasts; require cumbersome and error-prone manual data entry and evaluation; and typically operate at the chain level only. Inaccuracies and siloed decisions not only cause revenue loss due to sub-optimal clearance cadences and inventory stockouts and overstocks, but they also cause pain downstream. For example, when stores are called upon to fulfill unpredicted stockouts elsewhere, it causes that store’s P&L to be adversely impacted by the unplanned higher labor costs.

Retailers need a shared view of demand, by channel, that is based on advanced analytical forecasting that is updated throughout the season and underlies the entire merchandising lifecycle.

Overcome multichannel inventory management challenges to optimize in-season sales

To address these challenges, Retailers need to take an end-to-end approach that coordinates decisions across the entire merchandising lifecycle. Ideally, interconnecting and synchronizing key allocation, promotion, markdown, and transfer decisions around a common prediction optimization engine driven by AI algorithms and machine learning. Once deployed, such a solution would sell inventory at the best margin, while making sure that customers are satisfied and never unfulfilled.

Equally important is the need to present optimized predictions in a workflow that can be easily understood, believed, and implemented by the entire merchandising team. Transforming retail merchandising operations to an AI-driven, optimized omnichannel world requires the commitment of people as much as technology and data science.

Is such a solution possible? Yes! At antuit.ai, we pioneered the Omnichannel Inventory Optimization solution suite. To learn more, download the Solution Sheet.

Today’s retail merchandising teams can no longer cling to the spreadsheets that worked in the simpler days of the past. As an AI-driven solution provider, we saw the need to breakout of the same silo-thinking with solutions that offer recommendations that are reconciled to all aspects of the merchandising lifecycle and based on a common prediction optimization engine. At antuit.ai, we are delivering real results for our customers based on this goal.