The Replenishment Conundrum

Inventory is often the single largest investment a retailer makes. Each unit of this investment becomes productive when it enables a sale, i.e., when the consumer finds the desired item at the right time and location, and a transaction occurs. Doing so profitably is a formidable challenge, requiring millions of replenishment decisions daily. For each item/location/day, too little inventory increases the risk of lost sales, whereas too much inventory ties up capital unproductively.

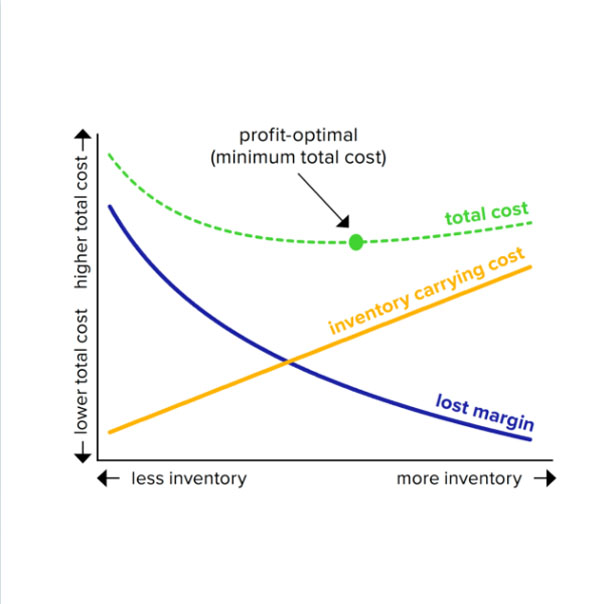

Finding the sweet spot between those two extremes and their associated costs: lost margin and inventory carrying costs, respectively, is a challenge with ramifications across several functions: supply chain & logistics, merchandising, and finance.

Most replenishment systems today have two common shortcomings:

- arbitrary rules based on weeks of supply, target service level, or similar logic disconnected from profit goals.

- broad-brush logic applied to entire categories and/or groups of stores regardless of their specific nuances.