Innovative companies are cutting supply chain complexity and accelerating responsiveness using artificial intelligence. By applying AI and machine learning against vast sets of supply chain data to unearth insights into problems and performance, enterprises are augmenting knowledge-intensive areas such as supply chain planning to be more dynamic, flexible, and efficient.

But is your organization ready for AI-powered supply chain planning? That’s a loaded question to answer. After all, enterprises employ staff across several departments. Making sure everyone is prepared for AI requires careful planning and communication.

It helps today’s leaders to break this question down into its constituent parts. Organizational readiness can be broadly divided into four areas and evaluated through a scorecard.

The 4 questions on an AI organizational readiness scorecard

1. Is my organization ready from a data availability perspective?

This should always be the first question that comes to mind. For starters, your organization should have internal data from the Enterprise Resource Planning (ERP) system available. Three years of sales history and transactional data is ideal. Additional key data elements include:

- Transaction data, such as, inventory history, current inventory position

- Pricing and promotion data

- Master data, such as SKUs, locations, lanes, manufacturing capacity, bill of material and customers

That said, there have been several advances in AI, especially related to machine learning, that can help fill crucial data gaps with representative data.

Let’s consider product demand, for example. It’s important to have continuous data points with no missing data to capture trends, seasonality and causality. The larger and more frequent data gaps there are, the larger the potential reduction of algorithmic accuracy.

One way to tackle this is by using the exponential weighted moving average based on neighborhood values. The nearest values to the data gap have the highest weights and vice versa. Weights can also be fine-tuned over successive future periods through feedback loops driven by comparison predicted to actual outcomes.

This is just one example of how machine learning can help your organization move forward with analytics when facing imperfect (or nonexistent) data. Even marginally improved predictions are better than none.

2. Are the employees at my organization ready to handle data analyses?

To make AI-powered planning a success, key personnel must have a basic understanding of optimization, statistics, and machine learning. Without this knowledge, they may be skeptical about the value that can be unlocked from new data-driven solutions.

To address these concerns, you should take the following two steps:

- Establish training programs to cover the basics of AI and related topics. It may be necessary to bring in HR and management within relevant departments to ensure the envisioned training programs can be properly executed.

- Identify champions of your enterprise’s new data-driven approach. These employees should focus on helping their colleagues understand the benefits of AI and the importance of additional training.

Don’t forget that for some initiatives, those outside your organization—stakeholders example customers, vendors, should give a buy -in.—. For example, if you are considering an advanced SRM portal (Supplier relationship management) initiative to improve indirect procurement KPIs such as P2P cycle time, it is imperative to engage your suppliers at an early stage.

3. Does my organization have robust processes in place for AI-powered planning?

We’ve said it before - the best solution is only useful when executed properly. In other words, your enterprise must have processes in place for incorporating data insights into workflows and decision-making.

Enterprises should have robust sales and operations planning (S&OP) processes in place. S&OP processes are important because they outline how leadership reviews and implements the changes to demand and sales projections. Processes are needed to disperse executive-level decisions throughout the organization.

A machine learning algorithm can provide significant results; however, execution is key as it impacts the bottom or top line in a firm. A well-established process ensures your business is reaping the full benefit of advances in data science.

4. Is your ERP system stable and well adopted? Is your existing planning system/APS delivering value?

The first question we covered in this post had to do with data availability within your ERP system. This, of course, rests on one crucial assumption: that your enterprise already has a stable, well-adopted ERP system.

From an organizational standpoint, having an ERP makes sense before moving forward with AI and machine learning initiatives. ERPs, by their nature, are used across departments. Many employees work with or are impacted by their organization’s ERP. A well adopted ERP system is ideal and lays a strong foundation for an AI infused planning system (APS). Critical assessment of your current APS can be based on quantifying the positive impact it has created on business KPIs. Typical KPIs that an APS can positively impact are – total supply chain cost, working capital cost, service level, and margin.

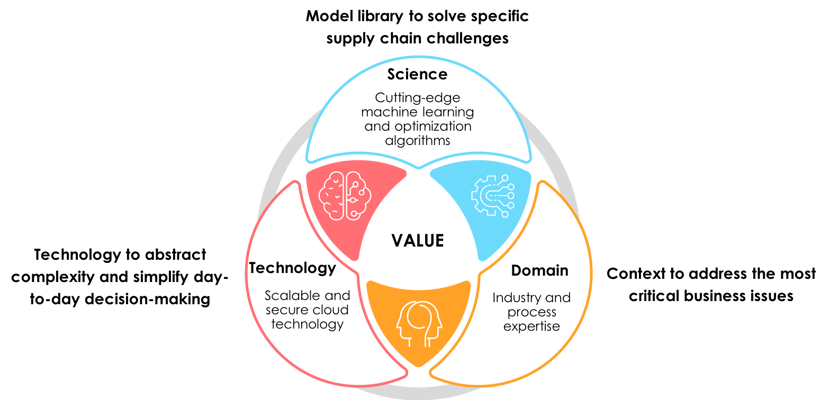

However, we believe APS alone is not the panacea. Sustained value generation is at the intersection of science, process and technology. A holistic approach is imperative to reap full benefits from an AI initiative.

Turn to partners to help determine your readiness

Preparing for AI-powered planning is an important step in organizational improvement and expansion.

So if you’re unsure how to score your checklist—or would like an outside perspective—consider turning to an expert partner. Reputable partners will be honest about the steps you need to take before becoming a data and AI driven organization.