During our very worthwhile appearance at NRF just a few weeks ago, quite a few questions from visitors to our booth revolved around the ongoing challenges affecting retail replenishment.

Nobody needs to belabor the problem—our post-pandemic economy is still plagued by unwieldy supply chain disruptions, leaving retail customers regularly disappointed with empty shelves—leaving them little choice but to consider competing stores (or online options) for everyday items they rely upon. From shoppers to store managers to C-level leadership, frustration is everywhere.

Simply accommodating the numbers is more complicated than ever. As a hypothetical example, a midsized national retailer with 1,000 stores may sell as many as 10,000 SKUs at each store—translating to 10 million periodic decisions to right-size inventory across every location. Who gets what, when, and how often?

Factor in the dynamics of lost unit sales—from that customer who makes an abrupt U-turn from a barren shelf—versus profit-eating carrying costs from slow-moving product languishing in warehouses and stockrooms. Our conversations with retail decisionmakers at NRF voiced a common refrain— ‘’we know we need to better leverage data” to sync replenishment with customer demand and achieve the elusive sweet spot for every SKU—minimized costs, maximized profits.

Many Vendors, Few Solutions

As in past years, that expo floor at the ‘Big Show’ in New York was a veritable sea of vendors, many touting their own software products for tracking replenishment. These tools are commonly limited by three inherent drawbacks:

- They operate around a broad, one-size-fits-all approach, typically with entire categories driven by arbitrary target service levels, while lacking advanced, granular-level capabilities for data-driven inventory optimization—maximizing the profitability of the inventory investment.

- The drivers of those replenishment policies (target service level, weeks of supply, etc.) are not directly connected to the desired end-goal: profitability.

- They may require an extensive—and usually capex-heavy—overhaul or ‘rip-and-replace’ of a retailer’s existing replenishment system(s).

A Brief Introduction to Replenishment AI

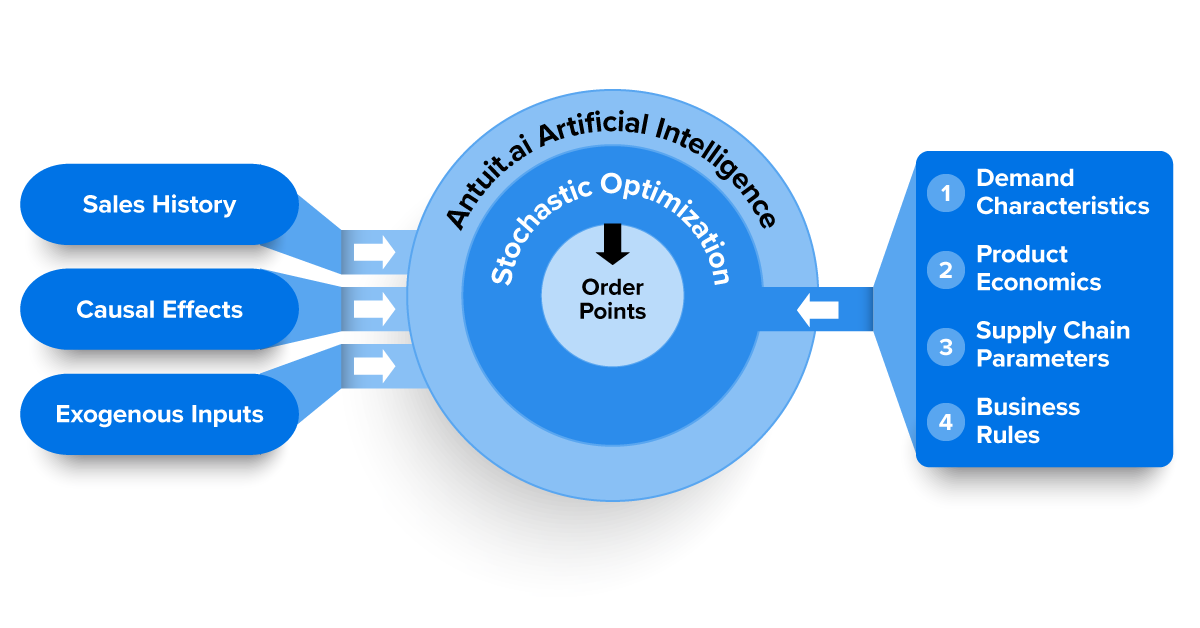

By contrast, our data-driven replenishment solutions are based around a pragmatic blend of AI/ML data science and Stochastic Optimization—a technique that explicitly incorporates demand uncertainty into the decision process to determine the optimal balance between “short” and “long” risks.

This pairing of techniques is analogous to the science behind autonomous driving vehicles, where an AI/ML acquisition layer “sees the world” around the car, interprets it, and projects the future possible states—distinguishing an ice cream truck from an ambulance—and predicting their likely paths. This information is then fed to an optimization engine, which achieves the object of driving from A to B under all applicable constraints (rules of the road, safety, navigation efficiency, etc.)

Similarly, an AI/ML layer interprets all available data to predict demand, relationships among products, responses to promotions, price changes, and other causal factors as well as contingent ones such as weather, disruptions, etc. This data is then consumed by a stochastic optimization engine whose goal is to maximize the expected profit at the individual SKU/store/replenishment cycle level, under all applicable business rules and constraints.

For retailers, the actionable data output includes a profit-optimized target inventory position, or what we call the order up-to-point (OUTP) for every product and store location, which in turn determines the suggested order quantity (SOQ).

AI + Stochastic Optimization Explained

Leveraged effectively, this powerful combination of AI/ML with Stochastic Optimization can consistently maximize the expected profitability of the total of every SKU across every store, over a given timeframe—eventually translating into a positive impact on P&L.

A Low-Touch, High-Impact Alternative

Not only can we offer a data-driven approach to profit-optimized replenishment, but deliver those benefits without that other common pitfall—an expensive end-to-end replacement of an existing replenishment system.

We’ve focused on creating an easily integrated, top-of-funnel solution that simply augments the longstanding replenishment system a retailer already has in place. We can draw another automotive analogy here—our solution is simply more potent, “high-octane” fuel for an existing replenishment engine.

Antuit.ai and Zebra: Our Combined Retail Expertise

One more advantage we can highlight today stems from joining forces with our new parent company, Zebra Technologies. Within just one year of our successful acquisition, our partnership with Zebra has afforded us an inside track toward integrating directly with Zebra’s industry-leading software and scanning hardware tools already relied upon by legions of global retailers every day. Our demand planning and replenishment tools provide a solid foundation for Zebra’s innovative Modern Store framework, which we were pleased to see formally unveiled at NRF.

Find Out More

For more information about AI-powered replenishment and our other demand forecasting solutions for retailers, contact us.